Piston Snubber Solutions for Noise and Pressure Reduction

In industrial environments, pressure fluctuations and system noise are more than just annoyances—they can be early warning signs of equipment stress, inaccurate readings, and long-term reliability issues. Whether you’re working with hydraulic systems, pumps, compressors, or high-pressure process lines, managing pressure spikes is critical for both safety and performance.

One of the most effective yet often overlooked solutions is the Piston Snubber. When used correctly, it plays a vital role in stabilizing pressure, reducing vibration, and extending the life of sensitive instruments such as pressure gauges, transmitters, and control devices.

This article takes a practical, non-sales-focused look at how piston snubbers work, why they matter, and how they fit into a well-designed measurement and protection strategy alongside components like Liquid Filled Gauges and Industrial thermowells.

Understanding the Problem: Noise and Pressure Spikes

Pressure systems rarely operate under perfectly steady conditions. Many industrial processes involve:

- Rapid valve opening and closing

- Pump pulsations

- Compressor cycling

- Sudden load changes

- Flow turbulence

These conditions create pressure surges, pulsations, and mechanical vibration. Over time, these forces can lead to:

- Inaccurate gauge readings

- Needle flutter and oscillation

- Premature gauge or sensor failure

- Increased maintenance downtime

- Reduced operator confidence in readings

Simply installing a pressure gauge without protection often leads to misleading data—and worse, a false sense of system stability.

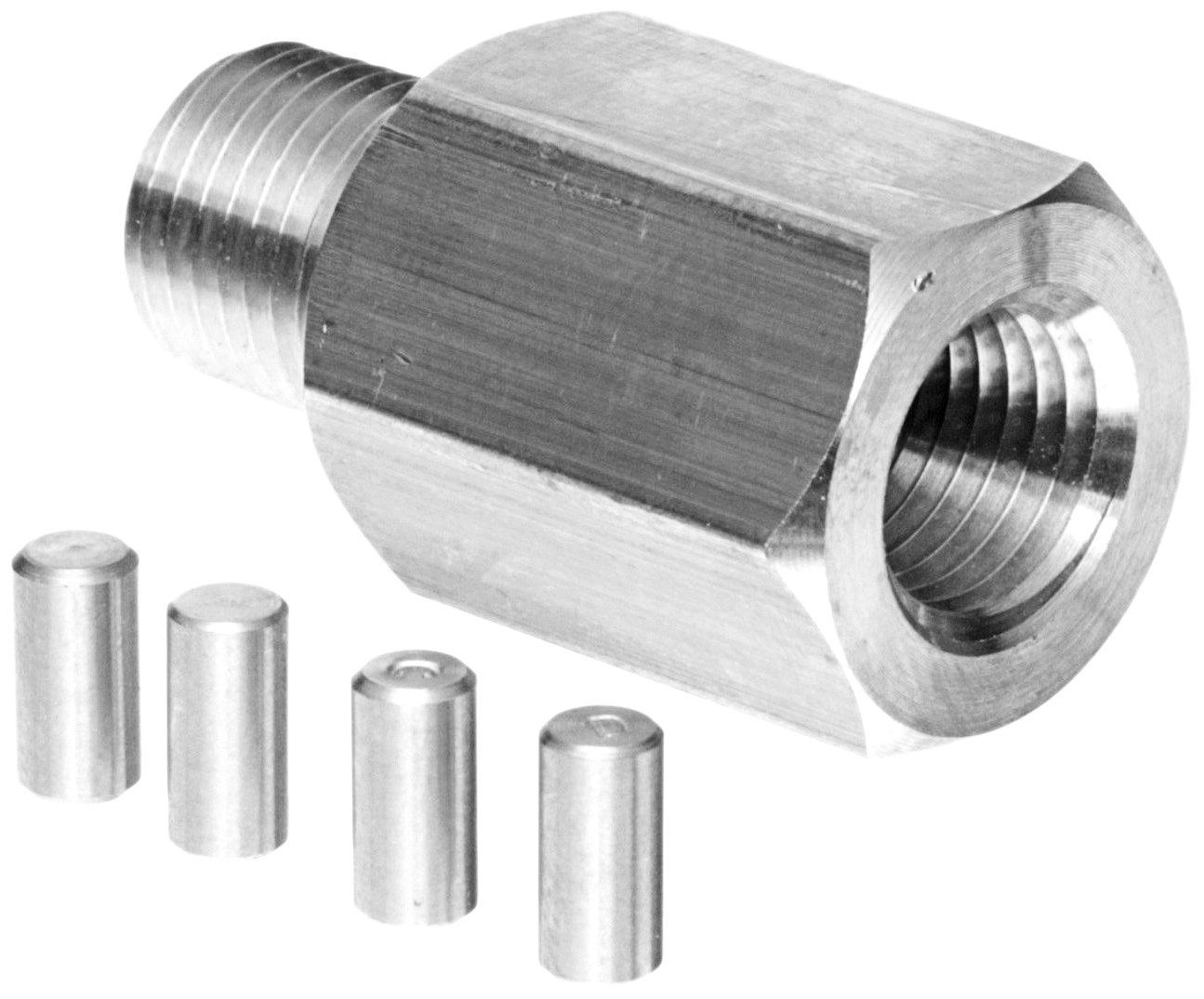

What Is a Piston Snubber?

A Piston Snubber is a mechanical device installed between a pressure source and a measuring instrument. Its purpose is to dampen sudden pressure changes before they reach sensitive components.

Unlike fixed-orifice snubbers, piston snubbers use a movable piston that responds dynamically to pressure changes. Under steady pressure, the piston allows fluid to flow normally. When a pressure spike occurs, the piston restricts flow momentarily, absorbing the shock and smoothing the pressure signal.

This design makes piston snubbers especially effective in systems with frequent or unpredictable pressure fluctuations.

How Piston Snubbers Reduce Noise and Pressure Fluctuations

1. Dampening Pressure Pulsations

Pressure pulsations from pumps or compressors can cause rapid oscillation in gauges. A piston snubber absorbs these fluctuations, delivering a more stable pressure signal.

2. Minimizing Mechanical Vibration

By limiting sudden pressure movement, piston snubbers reduce vibration transmitted to gauges and transmitters. This is especially important in high-cycle industrial environments.

3. Protecting Measurement Accuracy

Stable pressure equals readable, reliable data. Operators can trust the readings without second-guessing needle movement or digital signal noise.

4. Extending Instrument Lifespan

Repeated pressure shocks fatigue internal components. Piston snubbers reduce mechanical stress, helping instruments last longer and perform consistently.

Piston Snubber vs Other Snubber Types

Not all snubbers are created equal. Here’s how piston snubbers compare:

- Porous orifice snubbers: Simple and inexpensive but prone to clogging

- Needle valve snubbers: Adjustable but require manual tuning

- Piston Snubber: Self-adjusting, reliable, and better suited for dynamic systems

For systems with variable pressure behavior, piston snubbers offer a balanced solution without constant adjustment.

The Role of Liquid Filled Gauges in Noise Reduction

While piston snubbers manage pressure surges at the source, Liquid Filled Gauges address vibration at the instrument level.

These gauges are filled with glycerin or silicone oil, which:

- Dampens pointer vibration

- Improves readability in vibrating environments

- Protects internal mechanisms from wear

When combined with a piston snubber, liquid filled gauges provide dual-layer protection—one at the pressure line and one at the gauge itself.

This pairing is common in industries such as oil and gas, chemical processing, power generation, and heavy manufacturing.

Integrating Piston Snubbers with Industrial Thermowells

Pressure control is only one part of accurate process measurement. Temperature monitoring often faces similar challenges, including vibration, pressure, and mechanical stress.

An Industrial thermowell protects temperature sensors from harsh process conditions while allowing safe replacement without system shutdown. Like piston snubbers, thermowells act as a buffer between the process and the instrument.

When pressure and temperature instruments are both exposed to aggressive conditions, using:

- Piston Snubber for pressure lines

- Industrial thermowell for temperature probes

creates a comprehensive protection strategy that improves measurement reliability across the system.

Common Applications for Piston Snubbers

Piston snubbers are widely used across industries, including:

- Hydraulic and pneumatic systems

- Pump discharge lines

- Compressors and gas systems

- Chemical and petrochemical plants

- Power and steam applications

- Water treatment facilities

Anywhere pressure changes rapidly—or unpredictably—a piston snubber can reduce stress on downstream instruments.

Installation Best Practices

Even the best piston snubber won’t perform well if installed incorrectly. Some best practices include:

- Install the snubber as close to the pressure source as possible

- Ensure compatibility with process media (liquid, gas, corrosive fluids)

- Verify pressure and temperature ratings

- Keep connections clean to avoid debris interference

When paired with a Liquid Filled Gauge, ensure the gauge orientation supports proper fluid distribution inside the case.

Maintenance and Long-Term Reliability

One advantage of piston snubbers is their relatively low maintenance requirement. However, periodic checks help ensure consistent performance:

- Inspect for clogging in dirty or particulate-heavy systems

- Verify smooth gauge response over time

- Check seals for wear in high-temperature environments

Routine inspection aligns with preventive maintenance practices and reduces unexpected failures.

Why Stable Measurements Build Trust

Operators and engineers rely on instruments to make decisions—sometimes critical ones. Fluctuating readings erode confidence and increase risk.

By using piston snubbers, liquid filled gauges, and industrial thermowells together, systems deliver:

- Clear, stable readings

- Reduced noise and vibration

- Longer instrument service life

- Improved operational confidence

These benefits aren’t about selling components—they’re about creating systems people can trust.

Final Thoughts

Noise and pressure fluctuations are inevitable in industrial systems, but their impact doesn’t have to be. A Piston Snubber offers a simple, mechanical solution to a complex problem, especially when integrated with Liquid Filled Gauges and Industrial thermowells.

Understanding how these components work together helps engineers, technicians, and decision-makers design systems that are safer, more reliable, and easier to maintain.

When measurements are stable and instruments are protected, operations run smoother—and that’s a goal every industrial facility can agree on.